Cassette Deck Roll Forming Machine

- Price

- Contact us for price

- Condition

- New

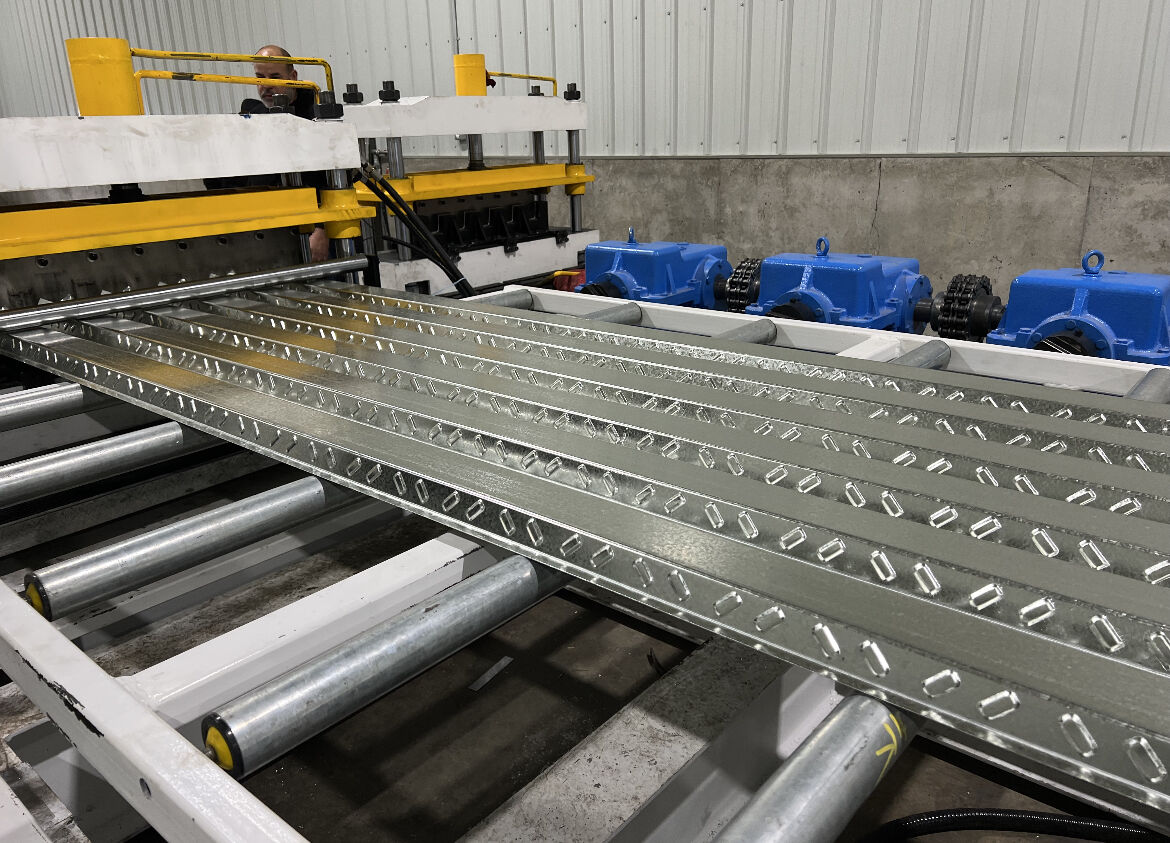

The Cassette Deck Roll Forming Machine is a high-performance, precision-engineered system designed to produce robust cassette deck profiles widely used in modern construction. Specifically built to handle metal sheet forming for building applications, this machine caters to the demanding needs of the UK construction industry, serving England, Wales, Scotland, and Ireland with reliable, customizable, and efficient manufacturing solutions.

Built to exacting standards and custom-tailored to each customer’s profile and operational requirements, the Cassette Deck Roll Forming Machine is ideal for producing metal decks used in flooring, roofing, and structural cladding applications. Its versatility, speed, and precision make it an indispensable asset for fabricators and contractors across a variety of industrial sectors.

Machine Technical Specifications

| Specification | Details |

|---|---|

| Machine Type: | Cassette Deck Roll Forming Machine |

| Production Speed: | Up to 18 meters per minute |

| Material Thickness Range: | 0.5 mm – 1.2 mm |

| Material Width Range: | 800 mm – 1250 mm |

| Material Types: | Cold rolled steel, galvanized steel, aluminum alloys |

| Material Yield Strength: | Up to 350 MPa (approx. 50 ksi) |

| Roller Material: | Hardened Steel Alloy |

| Roller Surface Treatment: | Precision Ground & Chrome Plated |

| Number of Forming Stations: | 18 – 22 stations |

| Roller Shaft Diameter: | 70 mm |

| Shaft Material: | High Strength Alloy Steel |

| Main Drive Type: | Servo Motor Driven |

| Power: | 380V, 50Hz, 3-phase (UK Standard) |

| Motor Power: | 11 kW |

| Cutting Method: | Hydraulic Shear |

| Blade Material: | High Strength Tool Steel |

| Control Type: | PLC with Touchscreen HMI |

| Operating Mode: | Automatic / Semi-Automatic |

| De-coiling System: | Hydraulic Uncoiler with tension control |

| Punching/Notching System: | Optional Hydraulic Punch/Notch Station |

| Machine Frame: | Welded Steel Construction |

| Thickness of Frame Steel: | 20 mm |

| Profile Shape: | |

| Profile Width and Depth: | Width up to 1250 mm; Depth up to 60 mm |

| Length Tolerance: | ± 2 mm |

| Safety Features: | Protective Covers/Guards, Emergency Stop Button, Overload Protection System |

Industries Served

-

Construction & Building: Used for residential, commercial, and industrial building decks, including mezzanine floors and roofing substrates.

-

Architectural Fabrication: Producing aesthetic and functional metal decks for architectural facades and exterior panels.

-

Infrastructure: Road, bridge, and public works requiring strong, lightweight decking.

-

Industrial Manufacturing: Components for factory buildings, warehouses, and structural platforms.

-

Agricultural Buildings: Metal decks for barns, storage facilities, and silos.

Machine Type & Capabilities

This roll forming machine is a fully automated, continuous production system designed to roll shape metal coil into cassette deck profiles with high accuracy and repeatability. It handles a variety of metals including steel and aluminum, forming them into precise deck profiles with integrated ribs for strength.

The machine incorporates features such as an automatic decoiler, precise servo-driven forming stations, and a hydraulic cutting system, enabling high-speed production with minimal waste. The system also supports optional punching and notching for secondary operations like bolt holes and drainage slots, tailored to customer specifications.

Typical Uses in Industry

-

Producing metal decking panels that serve as structural flooring elements.

-

Manufacturing lightweight, durable roofing substrates.

-

Creating custom architectural panels with ribbed profiles for enhanced load capacity.

-

Fabricating components used in mezzanine floors and raised platforms.

-

Supplying pre-fabricated decks for rapid construction site assembly.

Frequently Asked Questions (Q&A)

Q: Can the machine be customized to produce our specific cassette deck profile?

A: Yes, each machine is custom-built and can be tailored to your exact profile shape, width, and depth requirements.

Q: What is the lead time for manufacturing and delivery?

A: Production typically takes between 30 to 60 days. Shipping duration depends on the destination port within the UK, usually within 1-2 weeks after dispatch.

Q: What types of materials and thicknesses can the machine handle?

A: The machine is designed for cold rolled, galvanized steel, and aluminum coils with thickness ranging from 0.5 mm to 1.2 mm, and yield strengths up to 350 MPa (approx. 50 ksi).

Q: Is installation support available?

A: Yes, remote installation support via video guidance is offered, and on-site installation support can be arranged upon request.

Q: What warranty and maintenance support do you provide?

A: All machines come with a one-year warranty from the date of dispatch, along with durable maintenance and repair support services.

Additional Information

-

Location & Delivery: We supply and deliver new, custom-built Cassette Deck Roll Forming Machines throughout the entire United Kingdom including England, Wales, Scotland, and Ireland.

-

Customization: Machines are tailored to meet customer-specific profiles and production requirements, ensuring seamless integration into your manufacturing process.

-

Safety: Equipped with all mandatory UK and EU safety features to protect operators and comply with regulations.

-

After-Sales Support: Comprehensive training, technical assistance, and spare parts supply are available.

If you are looking to streamline your cassette deck production with a reliable, high-quality roll forming solution, this machine delivers both the precision and efficiency demanded by the UK market’s evolving construction industry.

Contact Seller Direct

To express an interest in this machine please submit the form below.