Metal roof flashing Roll Forming Machine

- Price

- Contact us for price

- Condition

- New

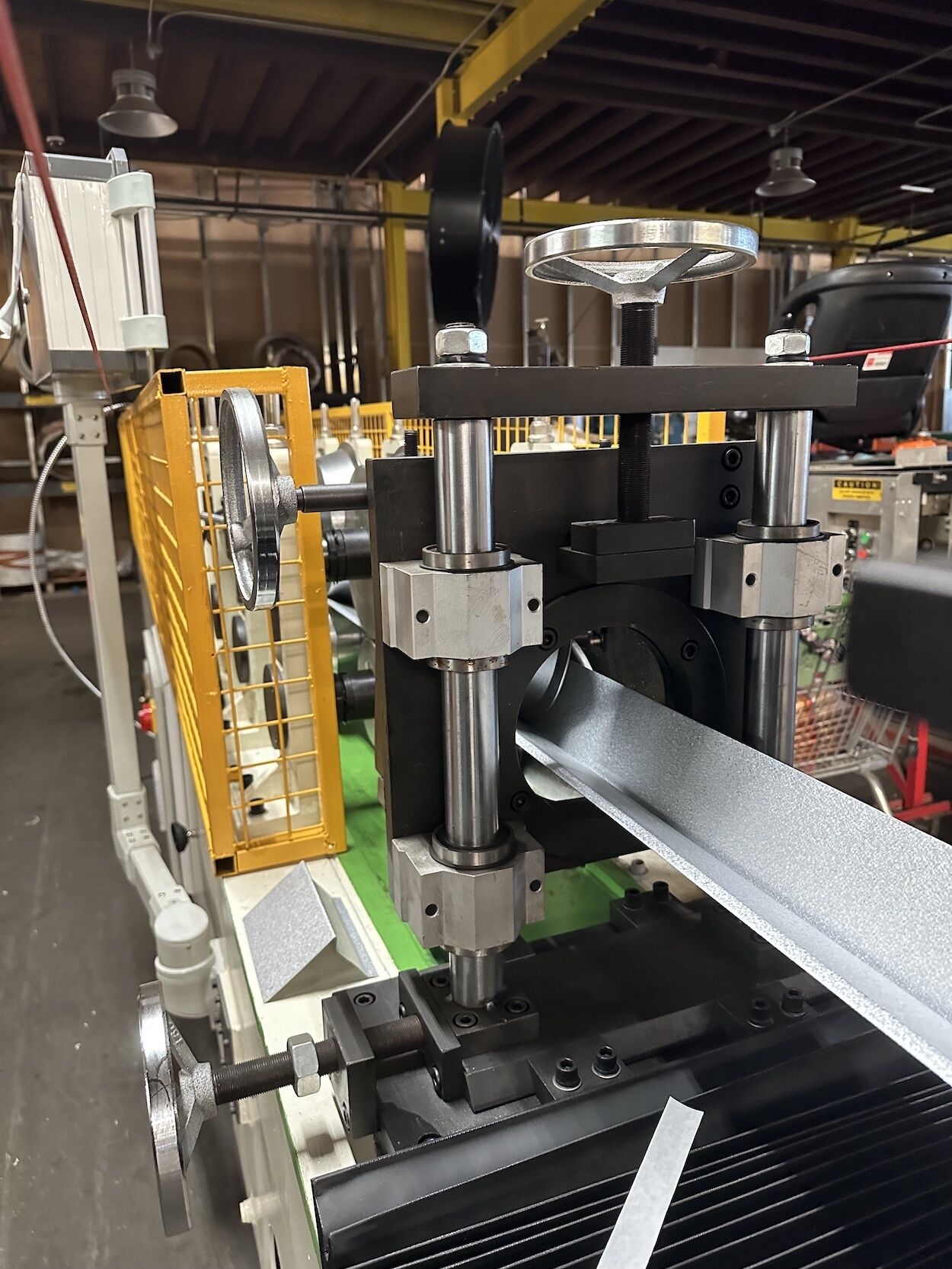

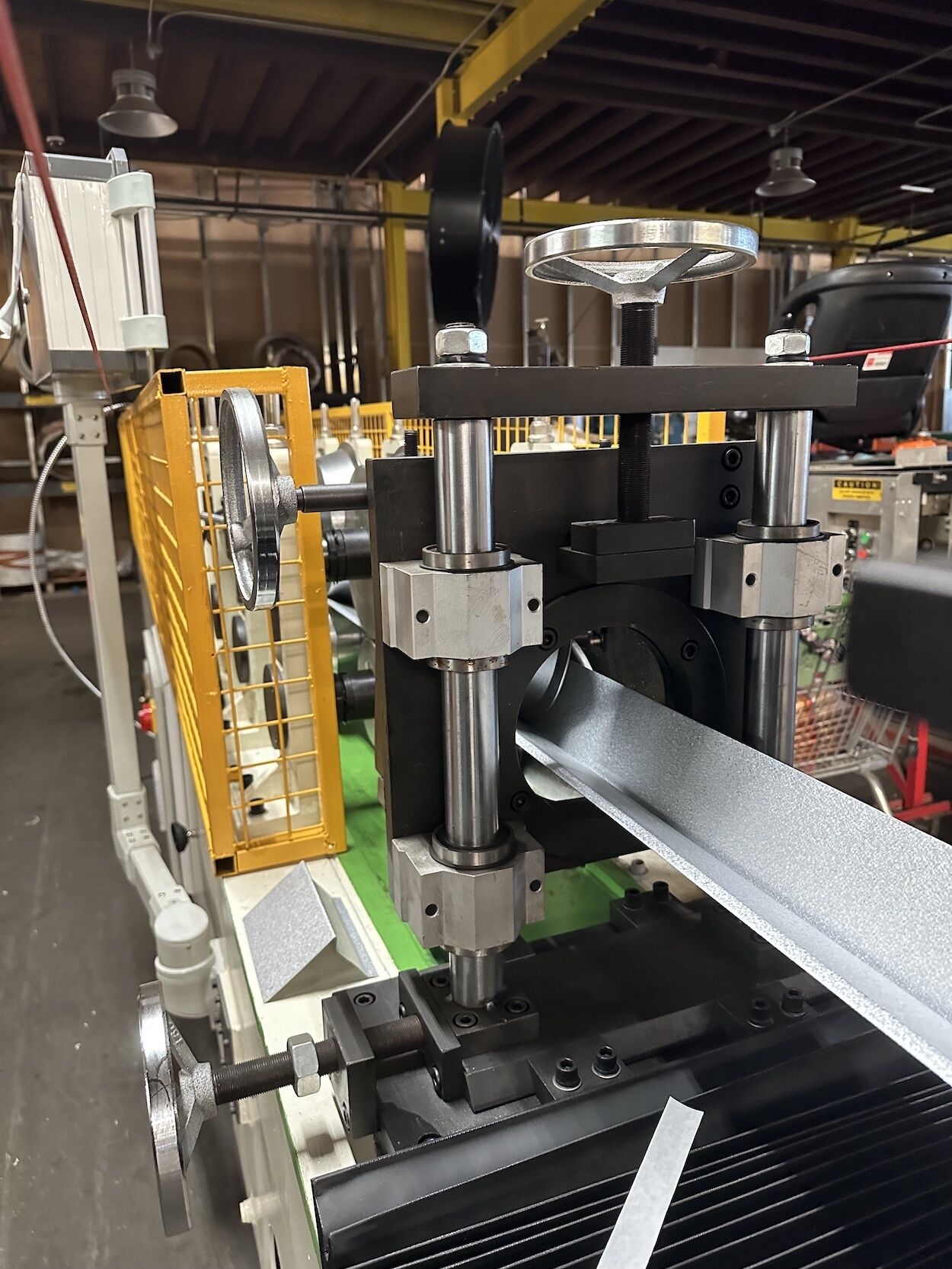

The Metal Roof Flashing Roll Forming Machine is a precision-engineered industrial solution designed to manufacture high-quality roof flashing profiles efficiently and consistently. Specifically tailored to the demands of the UK construction and metalworking markets, this machine covers all regions including England, Wales, Scotland, and Ireland.

Metal roof flashing is essential for weatherproofing and protecting buildings by sealing joints and edges on roofs. This roll forming machine produces a wide variety of flashing profiles with excellent dimensional accuracy, durability, and surface finish to meet stringent UK building standards and industry requirements.

Built with robust materials and advanced automation controls, this machine is ideal for manufacturers and fabricators involved in producing roof flashing components for residential, commercial, and industrial construction projects.

Machine Technical Specifications

-

Machine Type: Metal Roof Flashing Roll Forming Machine

-

Production Speed: Up to 15 meters per minute (adjustable based on profile complexity)

-

Material Thickness Range: 0.3 mm to 1.2 mm

-

Material Width Range: 300 mm to 600 mm

-

Material Types: Galvanized Steel, Aluminium, Stainless Steel, Pre-painted Steel

-

Material Yield Strength: Up to 550 MPa (80 ksi)

-

Roller Material: High-grade steel with hardened surface

-

Roller Surface Treatment: Chrome-plated or nitrided for wear resistance

-

Number of Forming Stations: 12 to 18 (depending on profile complexity)

-

Roller Shaft Diameter: 70 mm

-

Shaft Material: High-strength alloy steel

-

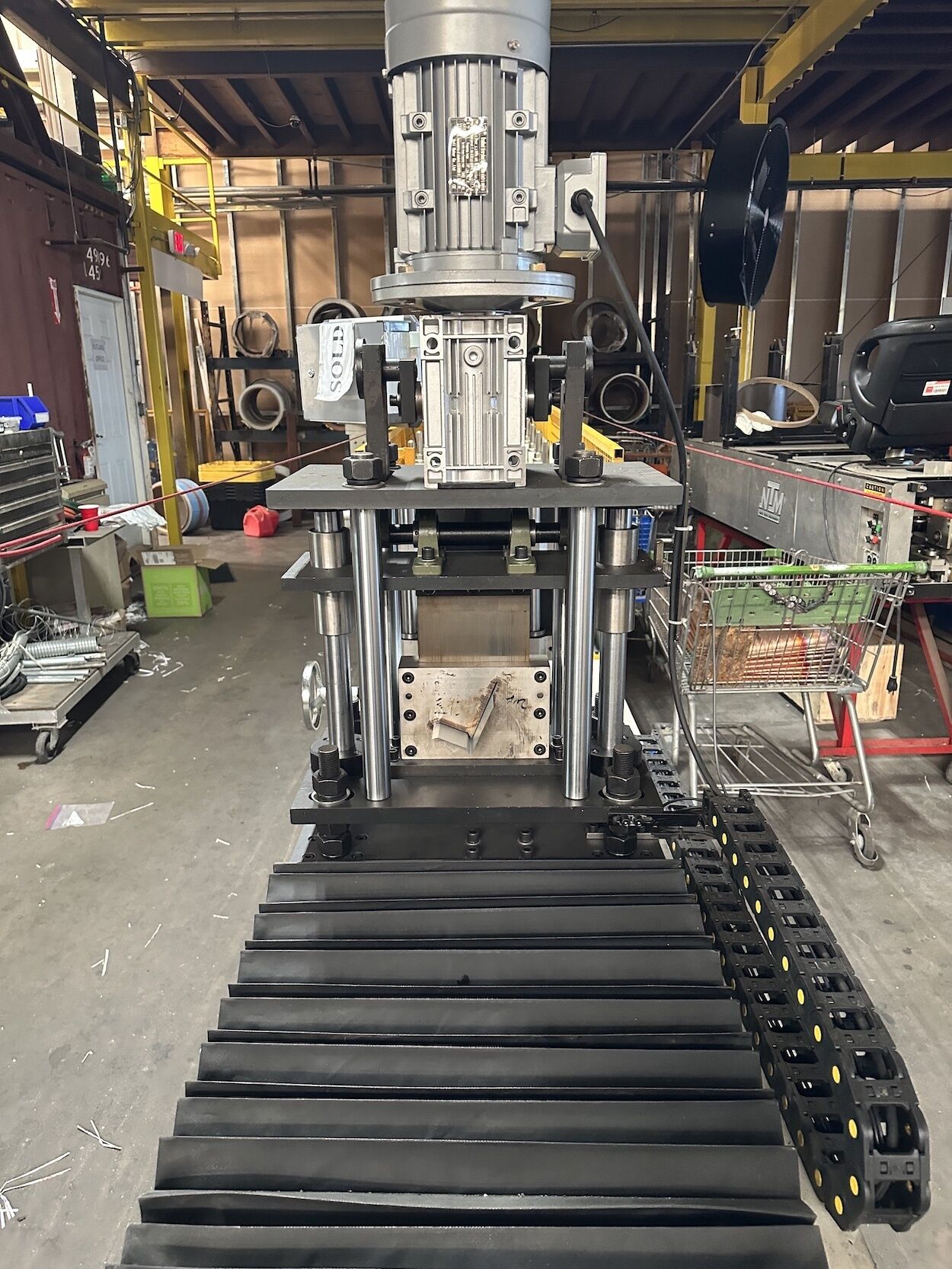

Main Drive Type: Gearbox-driven motor system

-

Power (for UK location): 380V, 50Hz, 3-phase supply

-

Motor Power: 7.5 kW (adjustable depending on machine configuration)

-

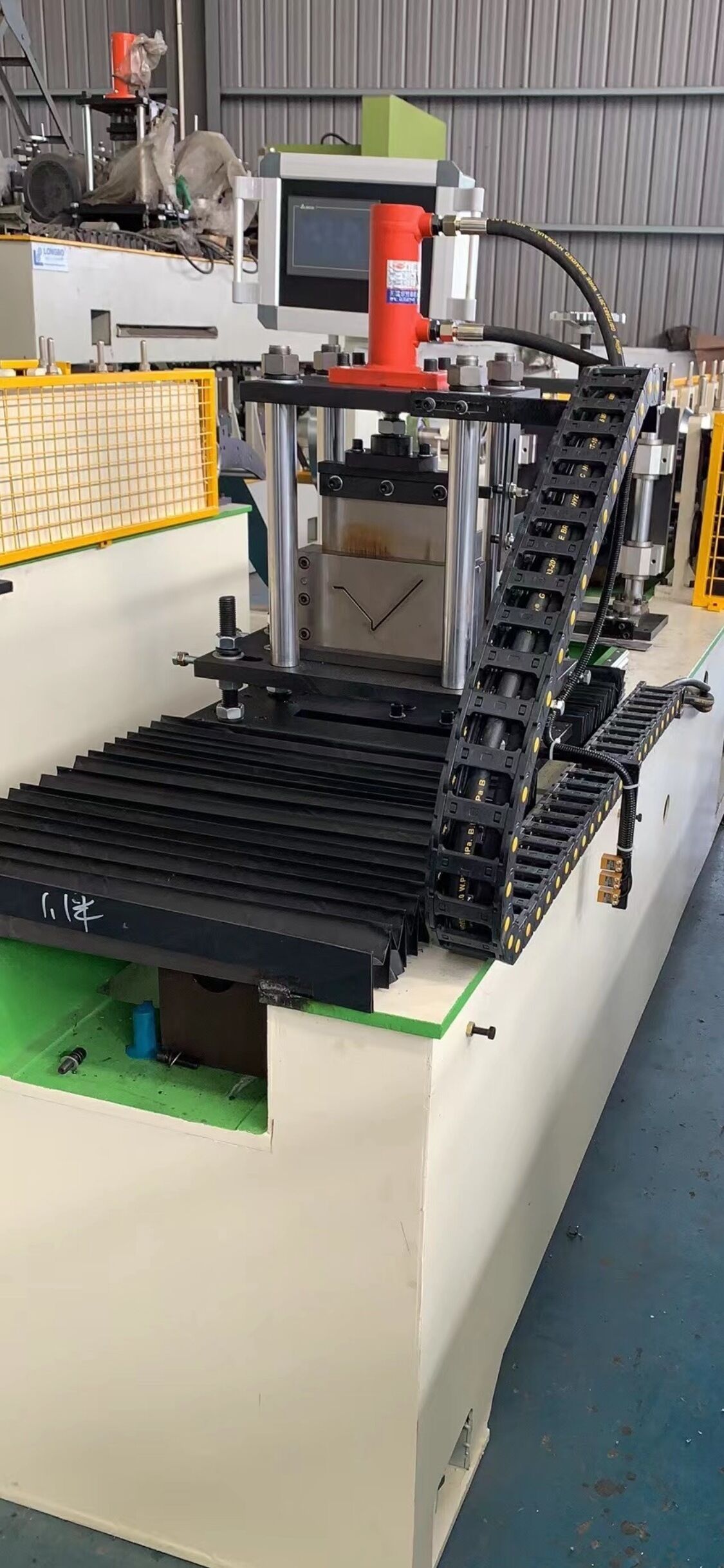

Cutting Method: Hydraulic guillotine cutting system

-

Blade Material: Tungsten carbide steel for long-lasting sharpness

-

Control Type: PLC control system with touchscreen HMI

-

Operating Mode: Automatic with manual override options

-

De-coiling System: Hydraulic uncoiler with automatic tension control

-

Punching/Notching System (if included): Hydraulic punch station for custom holes/notches

-

Machine Frame: Heavy-duty welded steel frame

-

Thickness of Frame Steel: 20 mm

-

Profile Shape: Custom profiles based on customer specification (e.g., L-flashing, step flashing, drip edge)

-

Profile Width and Depth: Variable depending on design; typical widths 50–150 mm, depths up to 50 mm

-

Length Tolerance: ±1.5 mm per 6 meters

-

Safety Features:

-

Protective covers and guards around moving parts

-

Emergency stop button accessible at multiple points

-

Overload protection system on motor and hydraulic units

-

-

Remote Installation Support: Yes, remote video guidance available. On-site installation can be arranged on request.

-

Lead Time for Manufacturing and Shipping: Typically 30–60 days manufacturing time; shipping times vary by destination port within the UK.

Industries Served

This Metal Roof Flashing Roll Forming Machine caters to various industries including:

-

Construction & Building: Production of flashing used in residential, commercial, and industrial roofing applications to ensure weatherproofing and structural integrity.

-

Metal Fabrication: Manufacturing of metal components used in cladding, roofing, and waterproofing systems.

-

Architectural & Structural Engineering: Custom flashing profiles for architectural detailing and building envelope solutions.

-

Agricultural Buildings: Flashing for barns, warehouses, and other agricultural structures to protect from moisture ingress.

-

Manufacturers of Pre-engineered Buildings: Component production for rapid construction systems.

Machine Type & Capabilities

This roll forming machine is designed to handle a wide range of flashing profiles with high precision and repeatability. Its capabilities include:

-

Producing complex bending profiles with consistent dimensional accuracy

-

Handling a variety of metal types and thicknesses common in UK construction

-

Automated length control and cutting for fast production cycles

-

Optional punching/notching stations to add holes or slots for installation purposes

-

Robust frame and hardened rollers to ensure long service life with minimal maintenance

-

User-friendly touchscreen interface for easy operation and profile switching

Examples of Use in Industries

-

Roofing contractors use flashing produced by this machine to seal joints around chimneys, vents, skylights, and edges, preventing water infiltration.

-

Metal fabricators integrate flashing profiles into panel systems for cladding and roofing assemblies.

-

Architectural detailers specify custom flashing designs for aesthetic and functional building finishes.

-

Manufacturers of modular buildings rely on flashing components to ensure quick and durable on-site installation.

Questions & Answers

Q: Can the machine be customized for our specific flashing profile?

A: Yes, all machines are custom-built to meet customer-specific profile requirements. The tooling and forming stations can be designed to produce the exact profile shape, size, and complexity you need.

Q: What type of materials can be processed with this machine?

A: The machine supports common materials such as galvanized steel, aluminium, stainless steel, and pre-painted steel with thickness ranging from 0.3 mm up to 1.2 mm, suitable for typical UK roof flashing applications.

Q: What is the typical production speed?

A: Depending on the profile complexity and material, production speeds can reach up to 15 meters per minute, allowing efficient batch or continuous production.

Q: What safety features are included?

A: The machine includes protective covers, emergency stop buttons located at strategic points, and overload protection systems to ensure operator safety.

Q: Is remote installation support available?

A: Yes, we provide remote video guidance for setup and operation. On-site installation and commissioning services are also available on request.

Q: What is the lead time for manufacturing and delivery?

A: Production usually takes between 30 and 60 days. Shipping times vary depending on your location within the UK, including England, Wales, Scotland, and Ireland.

Q: What warranty and support do you provide?

A: All machines come with a one-year warranty from dispatch, alongside durable maintenance and repair support to ensure your machine remains in optimal working condition.

Location & Delivery

This Metal Roof Flashing Roll Forming Machine is built new and to custom specifications for each customer. We proudly serve all of the United Kingdom, including England, Wales, Scotland, and Ireland. Our logistics solutions ensure safe and timely delivery to your site anywhere within these regions.

If you require tailored flashing production solutions for roofing or metal fabrication, this Metal Roof Flashing Roll Forming Machine offers reliable, efficient, and precise manufacturing support for your business in the UK.

Contact Seller Direct

To express an interest in this machine please submit the form below.