Metal Stud & Track Roll Forming Machine

- Price

- Contact us for price

- Condition

- New

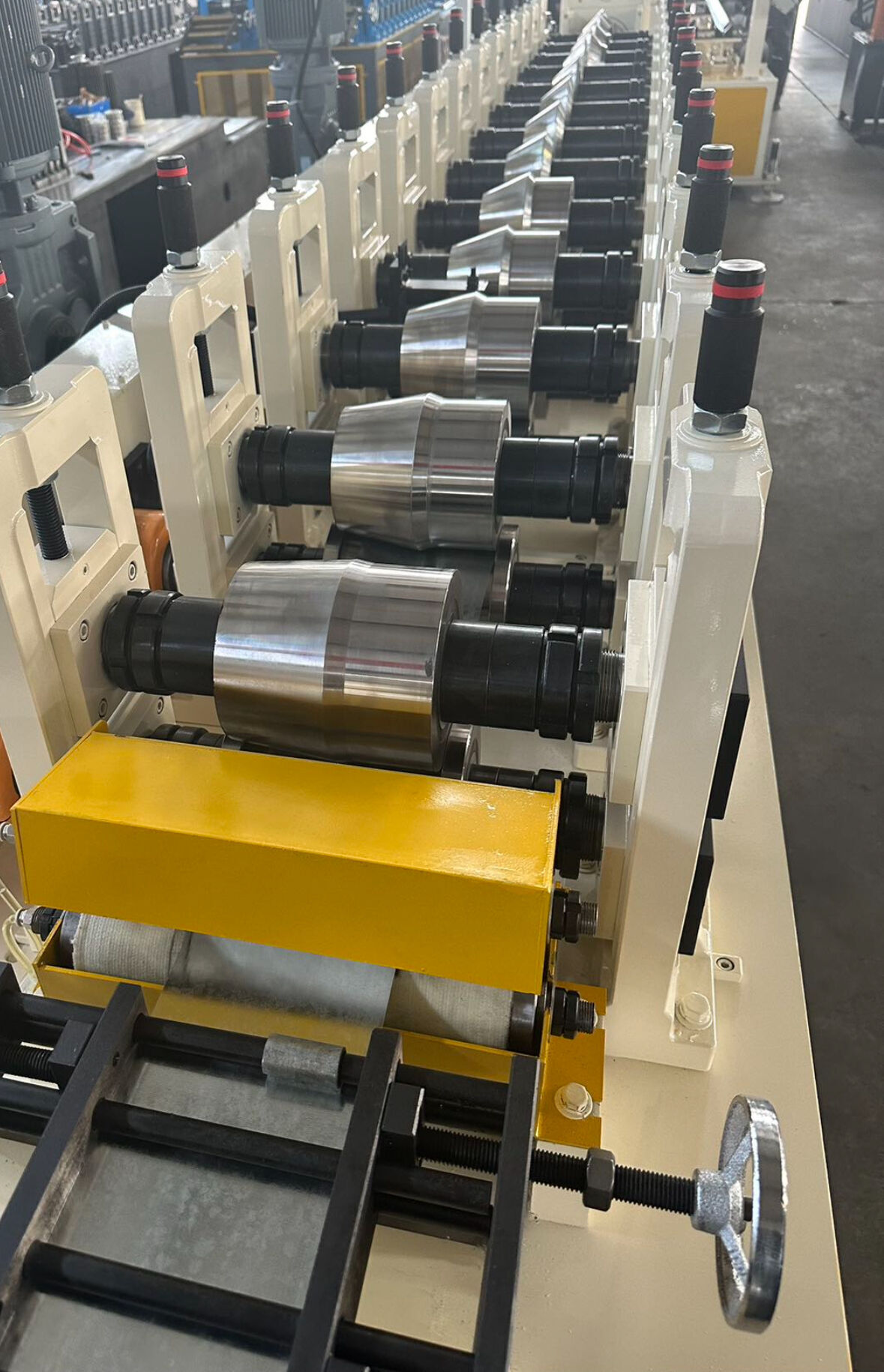

The Metal Stud & Track Roll Forming Machine is designed for high-precision, high-speed production of steel framing components used in drywall partitioning, ceiling grids, and light structural framing. This advanced roll forming system is built for customers throughout England, Wales, Scotland, and Ireland, ensuring a reliable, localised solution for the UK's construction and interior fit-out sectors.

This machine is custom-built to each customer's required profile dimensions and production specifications, offering versatility in stud and track profile shapes, widths, and depths. It is ideal for both small-batch runs and continuous, high-volume production. The system delivers straight, clean profiles with tight tolerances, minimal waste, and consistent performance — all backed by expert local support and a one-year warranty.

Machine Technical Specifications

-

Machine Type: Metal Stud & Track Roll Forming Machine

-

Production Speed: 30–60 metres per minute

-

Material Thickness Range: 0.4 mm – 1.2 mm

-

Material Width Range: 100 mm – 500 mm (depending on profile)

-

Material Types: Galvanized steel, cold-rolled steel, G550, G300

-

Material Yield Strength: Up to 550 MPa (80 ksi)

-

Roller Material: High-grade steel (GCr15)

-

Roller Surface Treatment: Hard chrome-plated for anti-corrosion and wear resistance

-

Number of Forming Stations: 12–20 stations (customizable)

-

Roller Shaft Diameter: 40 mm–70 mm (depending on machine capacity)

-

Shaft Material: High-strength 45# steel, precision ground and hardened

-

Main Drive Type: Chain drive or gearbox drive

-

Power (for UK): 380V / 50Hz / 3 Phase

-

Motor Power: 7.5 kW – 15 kW (based on configuration)

-

Cutting Method: Hydraulic cut-off (non-stop shearing or flying cut optional)

-

Blade Material: Cr12MoV steel, heat treated for long service life

-

Control Type: PLC control with touchscreen HMI

-

Operating Mode: Fully automatic or semi-automatic

-

De-coiling System: Manual or hydraulic decoiler (3–5 tons capacity)

-

Punching/Notching System (if included): Hydraulic pre-punching with interchangeable dies

-

Machine Frame: Welded steel base with side panels

-

Thickness of Frame Steel: 16 mm – 25 mm (varies by configuration)

-

Profile Shape: Stud and Track (U/C) Profiles

-

Q: Can the machine be customized for our profile?

A: Yes, machines are fully customized to your specific stud/track shape, size, and depth. -

Profile Width and Depth:

-

Stud: typically 35mm to 100mm width

-

Track: typically 38mm to 102mm width

-

Custom widths/depths are supported

-

-

Length Tolerance: ±1.0 mm per 3 metres

-

Safety Features:

-

Protective covers and roller guards

-

Emergency stop button

-

Overload protection system

-

Industries Served

The Metal Stud & Track Roll Forming Machine is primarily used in the construction and interior partitioning industries across the UK. These machines provide lightweight steel framing components essential for:

-

Residential Construction

For drywall partition walls and ceiling support systems in housing developments. -

Commercial & Office Fit-Outs

Fast-track interior wall and ceiling installations in offices, shopping centres, and commercial units. -

Hospitality & Healthcare

Partitioning in hotels, hospitals, and care facilities, where clean lines and non-combustible framing are essential. -

Educational Facilities

Installation of non-load-bearing walls and suspended ceiling systems in schools, colleges, and universities. -

Modular Building and Prefabricated Units

Metal studs and tracks are used as structural elements in prefabricated cabins and modular housing units.

Machine Type & Capabilities

This machine is a high-precision, automated roll forming system capable of:

-

Producing metal stud and track profiles of various sizes and gauges with interchangeable tooling.

-

Supporting high-speed and continuous production with automatic cutting and punching.

-

Allowing profile adjustment for different construction standards and dimensions used across the UK.

-

Offering fully programmable control for customized production runs, quick changeovers, and minimal downtime.

Examples of Use in Industries:

-

Drywall installers in Manchester, Cardiff, and Glasgow use the machine to fabricate U/C profiles on-site or in-house for rapid wall framing.

-

Modular builders in Belfast and Dublin benefit from repeatable, high-volume production with tight tolerances.

-

Interior contractors across London and Birmingham rely on the machine’s speed to meet tight construction schedules.

Common Questions & Answers

Q: What type of materials are normally used with this machine?

A: Galvanized steel (G300–G550), cold-rolled steel, with gauges from 0.4 mm to 1.2 mm and yield strength up to 550 MPa (80 ksi).

Q: Can this machine handle both stud and track profiles?

A: Yes, it is designed for both C-shaped studs and U-shaped tracks, and can be equipped with interchangeable tooling for rapid profile switching.

Q: Is remote installation support available?

A: Yes. We offer remote video guidance, and on-site installation is available upon request across all regions of the UK and Ireland.

Q: Can this machine be delivered across the UK?

A: Absolutely. We deliver and support machines in England, Wales, Scotland, and Ireland.

Q: What is the lead time for manufacturing and shipping?

A: Production usually takes 30 to 60 days, and shipping time depends on your specific delivery location within the UK or Ireland.

Q: Is the machine covered by warranty?

A: Yes. Every machine is backed by a 1-year warranty from dispatch, along with durable maintenance and repair support.

Delivery & Support

All machines are new, custom-built to your specifications, and can be delivered anywhere in the United Kingdom, including England, Wales, Scotland, and Ireland. We offer complete support from technical consultation, layout design, installation assistance, and training — all backed by a dedicated team in the UK.

For more details, or to request a quote tailored to your required stud & track profile, contact our Machine Matcher team. We ensure every machine is built to perform with accuracy, reliability, and long-term efficiency.

Contact Seller Direct

To express an interest in this machine please submit the form below.