Flashing & Trim Profile Roll Forming Machine

- Price

- Contact us for price

- Condition

- New

The Flashing & Trim Profile Roll Forming Machine is engineered for precision shaping of custom flashings, edge trims, corner pieces, and drip caps used widely across roofing and cladding projects. Designed to meet the highest standards of UK manufacturing, this roll forming solution is ideal for fabricators, builders, and metal roofing specialists across England, Wales, Scotland, and Ireland.

Capable of producing accurate, clean, and consistent profiles in a wide range of materials and gauges, this machine is essential for fabricating flashings and trims used to protect roofs, walls, and building joints from water ingress and enhance aesthetic finishes.

Whether operating in a high-output factory or as part of a bespoke fabrication setup, this machine delivers reliability, speed, and flexibility — all while being fully customizable to suit your exact trim profile requirements.

Industries Served

-

Roofing & Cladding Fabrication: For producing ridge caps, drip edges, barge trims, and gable ends.

-

Steel Building Systems: Flashings for steel-framed structures and pre-engineered buildings.

-

Construction & Contracting: On-demand trim production for residential and commercial sites.

-

Modular & Prefabricated Buildings: Producing high-volume custom trims for transportable structures.

-

Agricultural Buildings: Roof and wall trims for barns, silos, and sheds.

-

Rainwater Systems: Flashings around gutters, fascias, and drainage openings.

Machine Type & Capabilities

-

Machine Type: Flashing & Trim Roll Forming Machine

-

Functionality: Designed to form multiple trim types (Z, L, J, drip edge, ridge cap, custom angular flashings) in quick succession with minimum changeover time.

-

Operation: Automated feeding, forming, and shearing controlled via user-friendly PLC system.

-

Customizability: Tooling and forming stations can be configured to match any flashing profile width, angle, or return depth required by UK roofing standards.

Machine Technical Specifications

-

Machine Type: Flashing & Trim Roll Forming Machine

-

Production Speed: 10–25 meters per minute

-

Material Thickness Range: 0.3 mm – 1.2 mm

-

Material Width Range: Up to 1250 mm

-

Material Types: Galvanised steel, pre-painted steel, aluminium, copper, stainless steel

-

Material Yield Strength: Up to 550 MPa (80 ksi)

-

Roller Material: High-grade forged steel

-

Roller Surface Treatment: Hard chrome-plated for wear resistance and smooth finish

-

Number of Forming Stations: 10–18 (depending on profile complexity)

-

Roller Shaft Diameter: 60 mm

-

Shaft Material: Solid steel (high-tensile)

-

Main Drive Type: Chain drive or gearbox drive

-

Power (UK location): 3-phase, 380V, 50Hz

-

Motor Power: 7.5 kW – 11 kW

-

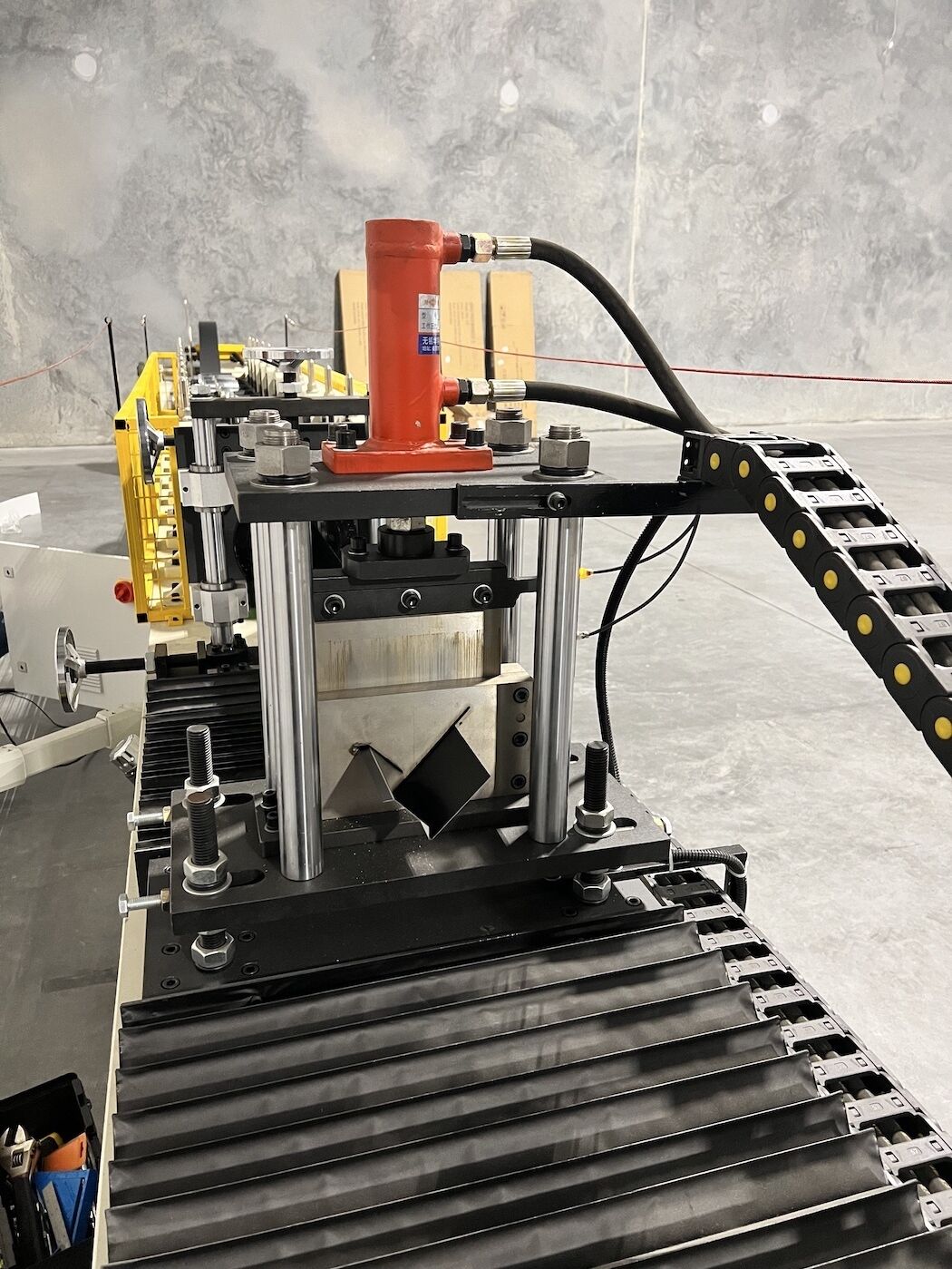

Cutting Method: Hydraulic post-cutting

-

Blade Material: Cr12MoV (heat-treated, wear-resistant)

-

Control Type: PLC with HMI touchscreen (English language interface)

-

Operating Mode: Fully automatic with manual jog/test options

-

De-coiling System: Manual or hydraulic de-coiler (3–5 tons capacity)

-

Punching/Notching System (if included): Optional hydraulic unit for slots or holes

-

Machine Frame: Welded steel structure, stress-relieved

-

Thickness of Frame Steel: 18 mm – 22 mm

Profile Shape & Dimensions

-

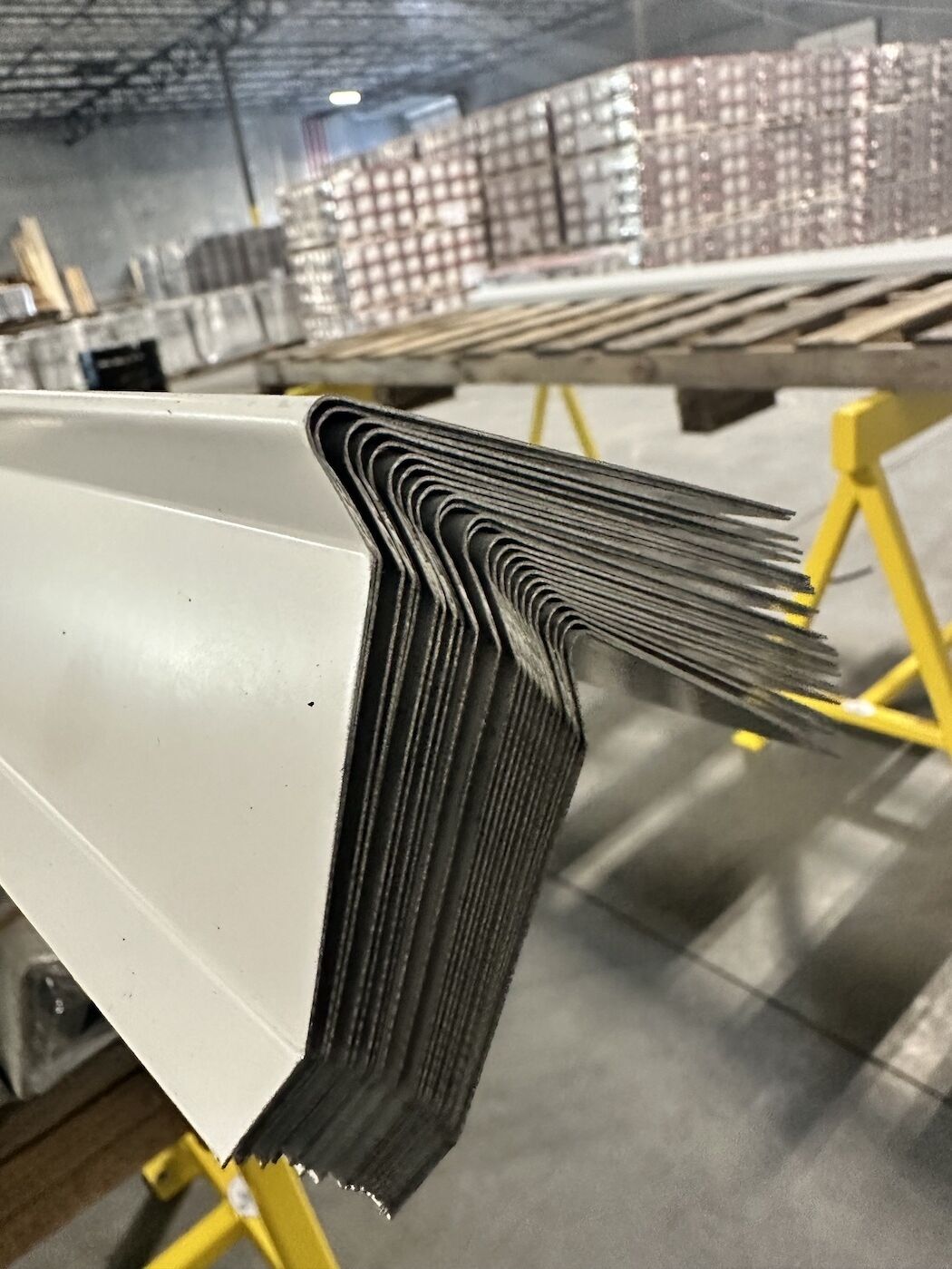

Profile Shape: L-shaped, J-trim, Z-trim, Ridge Cap, Drip Edge, Valley Flashing, Box Trim, Custom profiles

-

Q: Can the machine be customized for our profile?

A: Yes. All machines are custom-built to meet your specific trim or flashing profile. -

Profile Width and Depth: Fully customizable (typical widths range from 50 mm to 300 mm)

-

Length Tolerance: ±1.0 mm per 3 meters

Safety Features

-

Protective Covers/Guards: Installed over moving and rotating parts

-

Emergency Stop Button: Accessible on control panel and machine ends

-

Overload Protection System: Integrated to protect motors and electrical components

Installation & Support

-

Remote Installation Support Available: Yes. We provide remote video guidance as standard.

-

On-site installation: Available upon request across the UK and Ireland.

Delivery & Lead Time

-

Manufacturing Time: Typically 30–60 days depending on customization

-

Shipping & Delivery: Transit time depends on final destination within the UK or Ireland. Full logistical support is provided.

Material Details

-

Commonly Used Materials:

-

Pre-painted galvanized steel (PPGI) – 0.5 mm to 0.9 mm

-

Aluminium – 0.5 mm to 1.0 mm

-

Galvanized steel – 0.6 mm to 1.2 mm

-

Stainless steel or copper (optional)

-

-

Material Gauge Range: 26 – 18 gauge

-

Material Strength: Typically 40–80 ksi depending on material type

Service Coverage

All Flashing & Trim Profile Roll Forming Machines are new, custom-built, and delivered to any region within:

-

England

-

Wales

-

Scotland

-

Ireland (Northern & Republic)

Comprehensive support is provided throughout installation, commissioning, and operation. Machines are backed by a 1-year warranty from dispatch, along with ongoing maintenance and repair services.

Questions & Answers

Q: Can this machine produce multiple flashing profiles?

A: Yes, with modular tooling and adjustable stations, one machine can handle several flashing shapes with quick changeovers.

Q: Can the control system be programmed in English?

A: Absolutely. The interface is user-friendly, fully in English, and includes training.

Q: Is this machine suitable for both light and heavy gauges?

A: Yes, depending on tooling configuration, it can process from 0.3 mm up to 1.2 mm material thickness with strength up to 550 MPa.

Q: How long does installation take?

A: Remote video-assisted setup can be completed in a few days. On-site setup, if needed, typically takes 3–5 days.

Q: What is the machine's footprint?

A: Standard length ranges from 6 to 12 meters depending on number of stations. Custom layouts available upon request.

Q: Can the machine cut profiles to specific lengths automatically?

A: Yes, the PLC system allows pre-programmed lengths with tolerance control of ±1.0 mm.

For further details, availability, or to request a custom configuration, contact Machine Matcher. All machines are supplied brand new, tailored to your production needs, and supported by our UK and Ireland-based service team.

Contact Seller Direct

To express an interest in this machine please submit the form below.